Your cart is currently empty!

BLOG

World Tech News

Dive into a world of captivating narratives and insightful articles. Explore the latest trends and tech innovations with our engaging blog content.

Next-Gen Transparent Semiconductor Material Could Revolutionize Electronics

By AC Cruz

A pioneering team at the University of Minnesota has developed a cutting-edge transparent and highly conductive semiconductor material, a breakthrough that promises to enhance the efficiency of high-power electronics, particularly those requiring transparency, like lasers. This entirely synthetic material enables electrons to move faster while remaining transparent to visible and ultraviolet light, offering a rare combination of properties that unlock new possibilities in semiconductor applications.

Transparent conducting oxides, like this material, have already set new performance records, marking a significant leap in semiconductor technology. As a rapidly expanding trillion-dollar industry, semiconductors are the backbone of digital advancements worldwide, powering devices from smartphones to medical equipment. The latest innovation tackles the limitations of traditional materials, which typically compromise between transparency and conductivity. By achieving both, this new ultra-wide band gap material opens doors to ultra-durable electronics that perform in extreme conditions, ideal for high-power and optoelectronic devices.

In their groundbreaking study published in Science Advances, researchers focused on improving the “band gap” of materials—key to maintaining transparency while enhancing conductivity. Professor Bharat Jalan, a leading researcher on the project, emphasized that this achievement is a game-changer for deep-ultraviolet devices, which have faced performance constraints for years. This material’s unique properties not only support high-performance electronics in challenging environments but also pave the way for next-gen innovations that combine optical clarity with superior electronic functionality.

As technology and AI evolve, the demand for advanced materials with hybrid properties will only grow. This transparent semiconductor material stands at the frontier of these developments, offering a glimpse into a future where electronics are both faster and more efficient, with far-reaching implications for sectors reliant on high-power performance and optical transparency.

You have an idea for an electronic device. You’ve designed a PCB, chosen the necessary components, and are ready to start the manufacturing process. But one question remains to be answered: What material should your PCB be made of?

Between cost, thermal thermal and electrical properties, mechanical considerations, and even industry regulations, you may have tons of potential options or be limited to just a few.

To help you find the best possible material, we’ve put together this guide. In it, you’ll learn:

- What we mean by PCB material, and a few of the potential options you have access to.

- The various properties of PCB materials and how to evaluate them.

- Suggestions on which material may be best for your unique application and industry.

Let’s start by explaining the basics of PCB material.

Understanding PCB Material Basics

PCB material refers to the substrate and conductive layers that form the foundation of a PCB.

The substrate is typically an insulating layer. It provides structural support and electrical insulation, while the conductive layers, usually made of copper, create electrical pathways for electronic components.

The choice of PCB material affects everything from thermal management to mechanical stability and electrical performance.

Different Types of PCB Material

The most commonly used PCB material is FR-4, a glass-reinforced epoxy laminate. It offers a good balance of electrical insulation, mechanical strength, and cost-effectiveness, making it suitable for a wide range of applications.

However, FR-4 is far from the only option. Due to their superior dielectric properties, materials like polyimide and PTFE (polytetrafluoroethylene) are preferred for high-frequency applications.

- Polyimide: Known for its excellent thermal stability and flexibility. Ideal for flexible circuits and high-temperature environments.

- PTFE: Provides low dielectric loss. Commonly used in RF and microwave applications.

Each material has unique properties, benefits, and limitations, which we’ll detail in the sections ahead. It’s essential to match these characteristics with the specific requirements of the intended application.

PCB Material and Electrical Performance

The electrical performance of a PCB material directly impacts the functionality and efficiency of the electronic device. Key parameters to evaluate include the dielectric constant (Dk) and the loss tangent (Df).

- Dielectric Constant (Dk): Affects signal speed and impedance.

- Loss Tangent (Df): Indicates the material’s ability to dissipate energy.

For high-frequency and high-speed applications, materials with a low dielectric constant and low loss tangent are preferable.

Signal Integrity Matters

Signal integrity is especially important in high-speed data transmission. Poor signal integrity can lead to issues like crosstalk, signal attenuation, and electromagnetic interference (EMI). Choosing a PCB material with excellent signal integrity properties ensures that the signals remain clear and accurate, reducing the risk of data loss and communication errors.

Managing Heat with the Right PCB Material

Thermal conductivity and thermal expansion are also important electrical performance considerations.

- High Thermal Conductivity: Helps in effective heat dissipation. Vital for maintaining performance and reliability under high-power conditions.

- Coefficient of Thermal Expansion (CTE): This should be compatible with the components mounted on the PCB. Prevents mechanical stresses and potential failure during thermal cycling.

Evaluating the electrical performance requirements involves understanding each of the following:

- Dielectric properties

- Signal integrity

- Thermal conductivity

- Thermal expansion

Aligning these parameters with the application’s needs will help ensure your PCB performs optimally in its intended environment.

Evaluating the Mechanical Properties of PCB Material

The mechanical properties of a PCB material directly impact the board’s physical durability and structural integrity.

These properties determine how well the PCB can withstand physical stresses during manufacturing and operation:

- Flexibility and Rigidity: Depending on the application, PCB material may need to be flexible or rigid. Flexible PCBs, made from materials like Polyimide, are used in applications requiring bending and twisting. Rigid PCBs, often made from FR-4, are used where a solid structure is needed.

- Tensile Strength: This measures the material’s resistance to breaking under tension. High tensile strength is crucial for applications subjected to mechanical stress.

- Layer Count and Board Thickness: The number of layers and the overall thickness of the PCB can impact its mechanical performance. More layers and greater thickness generally enhance strength but may also increase weight and cost.

A PCB material with the right mechanical properties ensures the board can withstand the physical demands of its application, contributing to its overall reliability and lifespan.

Environmental and Chemical Resistance of PCB Materials

For PCBs that need to operate in harsh conditions, environmental and chemical resistance may be a critical factor in material selection. The right material can withstand exposure to moisture, chemicals, and extreme temperatures without degrading but may come with a premium price tag.

If you’re creating electronics for these kinds of harsh conditions, here’s what to look for when selecting a PCB material:

Moisture Resistance

Materials like FR-4 and PTFE provide good resistance to moisture, preventing performance degradation in humid conditions.

Chemical Resistance

Choosing materials that resist chemical attack, such as Polyimide, can ensure a PCB maintains functionality in environments where solvents or corrosive substances are present.

UL94 Flammability Rating

This rating indicates the material’s ability to resist burning. High ratings (such as V-0) are preferred for safety reasons.

Materials like FR-4 and Polyimide typically achieve high flammability ratings, making them suitable for applications requiring stringent fire safety standards.

Operating Temperatures

Different materials have varying levels of thermal stability. Polyimide, for example, performs well in high-temperature environments, making it suitable for aerospace and automotive applications where the PCBs are exposed to extreme heat.

Selecting the right material is key to ensuring your PCB functions well, even in the harshest environments.

The Manufacturing Process Compatibility of PCB Material

If controlling costs is one of your primary concerns, you’ll want to make sure you’re selecting a material that’s compatible with the most efficient production methods.

Here’s what to select for:

- Ease of Manufacturing: Materials like FR-4 are widely used because they are easy to work with and readily available. More specialized materials may require unique handling processes.

- Fabrication Techniques: Different materials are compatible with various fabrication techniques such as lamination, etching, and drilling. Ensuring compatibility can improve production yield and reliability.

- Material Availability: Some advanced materials might have longer lead times or limited suppliers. Ensuring material availability can help avoid production delays.

The right PCB material will help control costs and ensure consistent, high-quality boards with minimal error risk.

Regulations and Industry Standards Surrounding PCB Material

Governments and regulatory agencies around the world are continuing to push for greener, more sustainable, and safer materials and production methods. The PCB industry is no exception to this.

Compliance with standards is yet another critical consideration when selecting the right PCB material:

- Key Standards: Important standards include IPC (Institute for Printed Circuits) and RoHS (Restriction of Hazardous Substances). These standards govern aspects like material quality, environmental impact, and safety.

- Compliance Requirements: Materials must meet specific compliance requirements to be used in certain industries or regions. This includes environmental regulations and safety certifications.

- Certifications: Obtaining necessary certifications can be essential for market entry and customer assurance.

Choosing the right PCB material is the foundation of a safe and reliable board that meets the standards of your target market.

Selecting PCB Material to Meet Application-Specific Requirements

The intended application of your PCB will have a major influence on your choice of PCB material. For certain applications (i.e. aerospace), you may have requirements you’ll need to meet. Other applications may grant more leeway. In any case, tailoring the material choice to the specific application ensures optimal performance.

Consumer Electronics

Typically require cost-effective materials like FR-4. Durability and performance are balanced with cost considerations.

Automotive

High reliability and temperature stability are crucial. Materials like Polyimide are often used.

Aerospace

Requires materials with high performance in extreme conditions, such as PTFE for its thermal stability and low dielectric loss.

Understanding the specific demands of the intended application will help you narrow down your list of PCB material options.

The Cost Considerations of PCB Material

Cost is always a significant factor in PCB material selection. The goal is to balance performance needs with budget constraints to achieve an optimal solution.

Different materials come with varying price tags. FR-4 is generally cost-effective, while materials like Polyimide and PTFE are more expensive. Higher-cost materials often offer superior performance, but you’ll need to evaluate whether those performance benefits justify the additional expense.

Ultimately, the long-term cost of ownership should be your driving principle when it comes to this factor. Ask yourself if the potential savings from improved performance, reliability, and reduced maintenance will outweigh the added initial expense of those higher-performing materials.

Still Unsure About Which PCB Material to Choose? Imagineering Can Help

Selecting the right PCB material involves evaluating multiple factors, including electrical performance, mechanical properties, environmental resistance, cost, manufacturing compatibility, and compliance with standards.

By carefully considering these aspects and matching them with the application’s specific needs, you can ensure the optimal performance and longevity of your PCBs.

However, if you’re still unsure which material makes the most sense for your PCB, Imagineering can help.

RASPBERRY Pi Camera

Raspberry Pi sure is doubling down on artificial intelligence with its recent accessory releases. The excellent Raspberry Pi AI Kit brought 13 TOPS of AI compute to the Raspberry Pi 5 by strapping a general-purpose Hailo-8L M.2 AI accelerator module onto it using the power of the PCIe-based M.2 HAT+.

The new Raspberry Pi AI Camera takes a different approach, bundling the AI accelerator together with the image sensor itself and exposing all the AI goodness through the camera connector, a standard interface that’s been present on almost every Raspberry Pi board for years now. This is all facilitated by the new Sony IMX500 image sensor (more on it in a second), with Raspberry Pi’s own RP2040 making a surprise cameo handling comms duty.

If you haven’t already, consider checking out our in-depth review of the Raspberry Pi AI Kit, as there will be comparisons between the two in this article – especially given how different yet similar they are in some regards. While we’ll stop to explain and provide some context where needed, having some prior insight into how the Raspberry Pi’s AI ecosystem works – and why you’d even want local AI in the first place – can help tremendously.

We want to thank Raspberry Pi for providing us with a review unit of the camera. It’s a pre-release copy which came in generic packaging, so we can’t take photos of the very snazzy retail box or say much about the unboxing experience. And for those playing along at home: if you see any hardware differences between your unit and the one in our photos, don’t worry too much about it – this is the reason why.

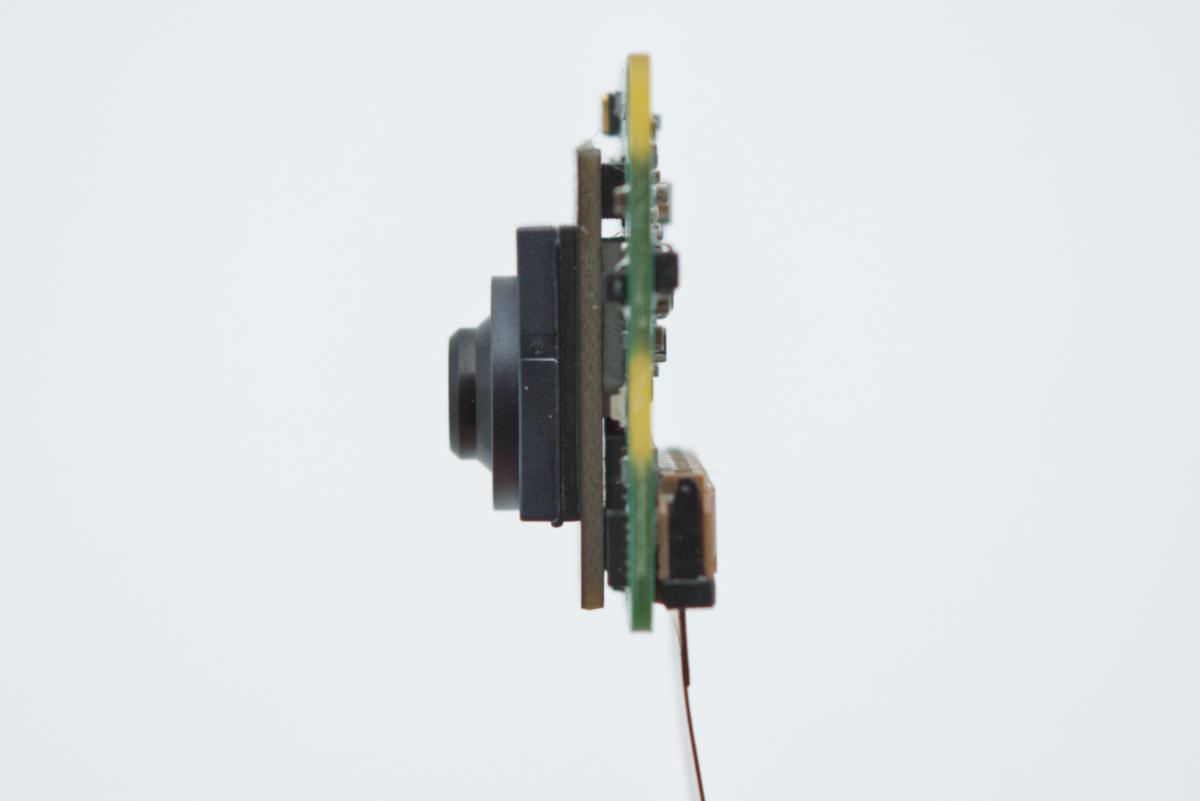

Hardware overview

The physical design of the Raspberry Pi AI Camera will come as no surprise to anyone who’s ever handled any of Raspberry Pi’s other camera modules. With its 24 x 25 mm footprint and all the mounting holes in their standard locations, the Raspberry Pi AI Camera should be a drop-in replacement (as long as you make sure that there’s extra clearance in your design for the bulkier sensor package and extra components on the PCB itself). The little 3D printed camera holder we’ve been using for a while now still works just fine.

The two modules are essentially the same size | photo: magazin Mehatronika

Sony’s IMX500 Intelligent Vision Sensor is behind all the AI magic here. By combining a 12.3 MP image sensor and an NPU into one single package, it enables efficient on-device inferencing without the need for any extra AI acceleration hardware. Sony unfortunately doesn’t provide a TOPS rating (and is in general a bit secretive about the sensor), but does list a Full/video + AI processing framerate spec on their key specifications page. The associated 30 FPS figure is a bit open-ended as there’s no info on the AI model used to obtain it – or is it some sort of hard limit? Does the video framerate automatically get capped to 30 FPS when the built-in NPU comes online to prevent overheating? We can’t know for sure unless Sony decides to push out the complete datasheet.

The sensor’s NPU doesn’t operate on the full-resolution video stream, but rather a scaled-down input tensor produced by a simple on-board ISP. The largest input tensor which can be handled has a dimension of 640 x 480 pixels (though naturally, more demanding AI models will likely require even lower input resolution, which can be dialed all the way down to just 64 x 48 pixels). In turn, the NPU spews out an output tensor which gets sent over to the host system to be displayed or for any extra computation required.

Unlike regular camera modules which only stream image data, the Raspberry Pi AI Camera thus has an extra inference stream to push out. This stream, containing all the output tensors, gets sent to the Raspberry Pi over its CSI-2 camera interface – the same one already used by the image stream. Bunching the two up together is a very sleek solution for a number of reasons, but most importantly it allows the Raspberry Pi AI Camera to work on every single Raspberry Pi system equipped with a camera connector.

Some of you might recall that we mentioned an RP2040 a few paragraphs ago. What’s it doing in here? Well, this chip mainly facilitates file transfers and acts as an intermediary between the OS and the IMX500, functioning as an I2C-to-SPI bridge. In order to run an AI model, the IMX500 has to load it into its internal 8 MB memory. Naturally, models have to first be quantized, compressed, and packaged into something Sony calls a firmware file that’s compatible with the sensor’s NPU – and care needs to be taken to ensure that these actually fit into the very limited space available (especially since the 8 MB is shared between model storage and runtime memory).

Hold up – we hear you say – just 8 MB of memory? Why not just share the Raspberry Pi’s significantly larger RAM?

There are a few reasons. The IMX500 is designed around the concept of being fully self-contained, memory included. AI models require fast memory access, and the only way to facilitate that when sharing system memory is by using a suitably fast bus for connecting your AI gizmo to the host hardware. PCIe is a logical choice here, which is precisely why many standalone AI accelerators come as M.2 modules. This works great as evidenced by the Raspberry Pi AI Kit, but does come with a caveat: the only Raspberry Pi board which features a PCIe connector is the Raspberry Pi 5! By having its own memory pool, the Raspberry Pi AI Camera has to send much less data back and forth and can make do with just the camera connector, making it compatible with all Raspberry Pi boards.

Okay, that explains the benefit of having memory integrated right into the camera, but still doesn’t explain why there’s so little of it. We have no way of benchmarking how fast the chip’s on-board memory is, but we have reasons to suspect it’s faster than conventional RAM, likely being similar in design to CPU cache memory. This type of memory is significantly more expensive, which could explain the 8 MB figure – but ultimately, it’s likely that the choice boils down to Sony simply having to cost-optimize the IMX500.

The IMX500’s memory is volatile, so Raspberry Pi included an extra 16 MB of on-board flash storage specifically meant for caching recently used firmware files. This should allow for much quicker model initialization as opposed to beaming the data via I2C every single time. That built-in RP2040 handles all the caching automatically – so you likely won’t even know that it’s happening. Neat!

The lens element doesn’t have autofocus capabilities | photo: magazin Mehatronika

Let’s turn our attention to the camera part of the entire “AI Camera” concept – and for what it’s worth, it’s a pretty capable little imaging setup. The IMX500 is based around a 12.3-megapixel (4056×3040) 1/2.3 type sensor with a pretty decent readout rate – up to 60 FPS when shooting full-resolution and 4K video and 240 FPS for 1080p video as per Sony’s spec sheet. With that being said, the Raspberry Pi’s own encoding speed limitations cap camera framerates to 60 FPS for 1080p video, and ~10-15 FPS for 4K footage (mind you, these numbers are for the Raspberry Pi 5, and older models could perform worse). And then you’ve got the camera interface bandwidth which in practice limits framerates even further, usually down to 10 FPS for higher-resolution streams, and somewhere between 30 FPS and 50 FPS for 1080p video, depending on the sensor.

Raspberry Pi’s IMX500 driver implementation offers only two video modes: 4056x3040p10 and 2028x1520p30. We’re not sure whether additional modes were omitted given the camera’s AI-centric intended use (because of that mysterious 30 FPS Full/video + AI processing limit), or whether there was simply no suitable video mode on the sensor itself that could provide a faster framerate without overloading the Raspberry Pi in some way.

The AI Camera has no autofocus, but the small sensor size gives them a pretty deep depth-of-field that stretches from 20cm all the way to infinity. If need be, focus can be manually tweaked by twisting the lens.

This is all to say that the Raspberry Pi AI Camera can be used as a decent stills and video camera in a pinch – but if that’s all you’re after, the $70 asking price is a bit much. The $25 autofocus-enabled Raspberry Pi Camera Module 3 is a much, much better choice, especially when you take into account its wider range of video modes and even some slow-mo (120 FPS) shooting options.

But instead of talking about what the new camera isn’t meant for, let’s focus on its AI features. In order to check them out we have to turn to the software, which leads us to…

Hands-on with the Raspberry Pi AI Camera

Raspberry Pi’s hardware is excellent, but it’s the software support that sets it apart. Just like the Raspberry Pi AI Kit, the AI Camera integrates tightly (perhaps even more so) with Raspberry Pi’s existing software stack. The easiest way to get started is using rpicam-apps, Raspberry Pi’s handy camera application suite, but full integration with the Picamera2 Python libraryis also available for those needing programmatic access to the IMX500 from their Python scripts.

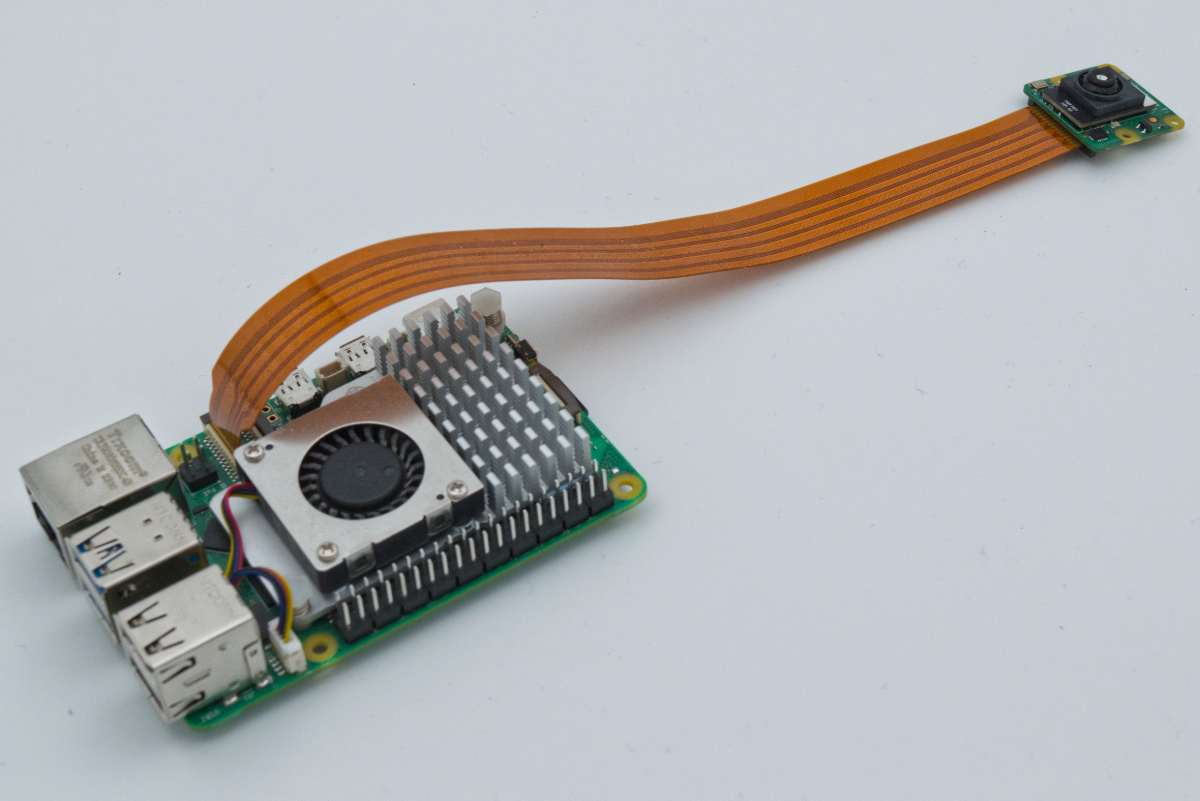

There’s a benefit to the AI Camera’s simple connectivity even when used with the Raspberry Pi 5, as it leaves the PCIe connector free for attaching storage | photo: magazin Mehatronika

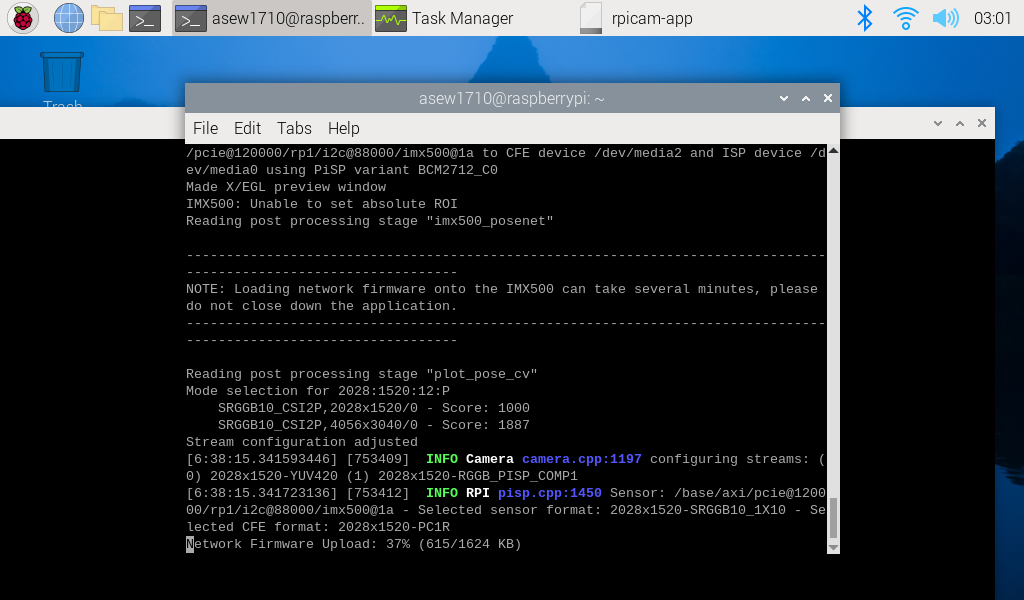

But before you can run anything or start tinkering away, it’s necessary to download the imx500-all support package using apt which contains all the required firmware files, post-processing stages, AI models to get you started and Sony’s model packaging tools.

Just like with the Raspberry Pi AI Kit, the AI Camera’s integration magic with rpicam-apps happens through post-processing stages. It’s best to imagine these as filters of sorts which occupy slots in the post-processing pipeline. Each stage performs a certain operation (or set of operations) to the image – be it simple things like color filtering or superimposing text, or more involved computing tasks like AI operations.

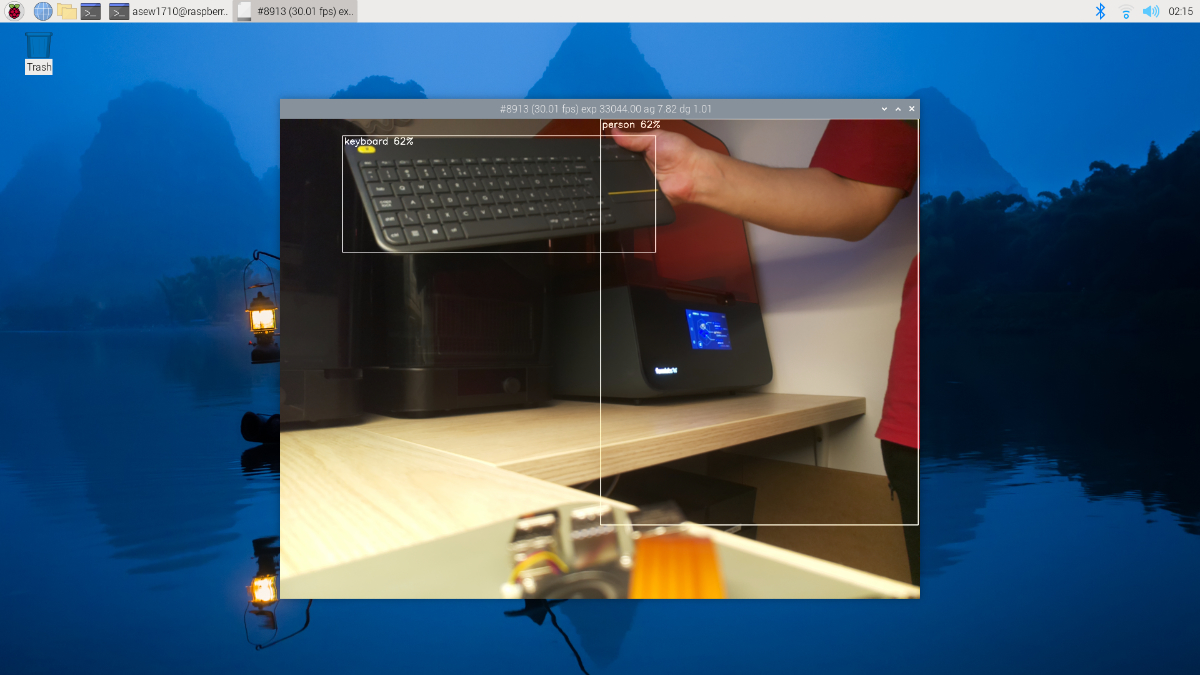

There are two built-in demos. These somewhat mirror the ones we’ve already seen running on the AI Kit’s Hailo-8L. In fact, while the Hailo-8L demos use different AI models, it seems that the same respective visualization stages got reused for object detection and pose estimation demos on both platforms. Let’s first run the MobileNet SSD-based object detection demo:

rpicam-hello -t 0s –post-processing-file /usr/share/rpi-camera-assets/imx500_mobilenet_ssd.json –viewfinder-width 1920 –viewfinder-height 1080 –framerate 30

…is this technically a Pi selfie of sorts? | screenshot: magazin Mehatronika

Woah – pretty sleek! It’s kind of impressive that most of what’s happening here is going on in the little camera module, with the host Raspberry Pi doing minimal processing work to simply render the scene and object detection boxes in the preview window. This is also evident in Raspberry Pi OS’ task manager – the CPU is mostly idle, with its utilization sitting at ~10%. Awesome.

Now onto the second demo, a pose estimator based on PoseNet:

rpicam-hello -t 0s –post-process-file /usr/share/rpi-camera-assets/imx500_posenet.json –viewfinder-width 1920 –viewfinder-height 1080 –framerate 30

Works just as well – and the CPU load stayed similarly low. On the Raspberry Pi AI Camera, both of the demos we’ve run work with an input tensor size of 640 x 480 pixels. There were no framerate drops, with the NPU delivering a smooth 30 FPS, and the whole experience was genuinely good. From an end-user standpoint, we couldn’t be happier.

Aside from freeing up the CPU for other tasks, AI accelerators generally improve a system’s power efficiency. We were measuring power draw of the entire system during the demos, and got a reading of 6.5 W at the wall. If we assume a ~90% power efficiency figure for the PSU, that works out to just 5.85 W. Impressively low!

In fact, this means that this IMX500-based setup draws some 40% less power than the already extremely efficient Hailo-8L setup from the Raspberry Pi AI Kit. The latter draws around 9.7 W during inferencing – though it provides significantly more performance.

To put both of these numbers into perspective, running AI tasks on the main CPU puts quite a hefty strain on it, which also shows up in the power draw. We managed to obtain a ~13.3 W full-system figure during testing – and the performance wasn’t great at all.

The IMX500 firmware upload in question here took around a minute to complete | screenshot: magazin Mehatronika

When loading a model up for the first time, there’s nothing cached in the on-board flash, so the entire firmware file has to get copied over from your Raspberry Pi onto the AI Camera. This can take a little while. Once cached, the firmware loads within seconds during subsequent runs. We’re also pretty happy to report that the system is capable of keeping not just one, but several recent firmware files in cache.

That’s great – but what about developing your own applications or even bringing custom AI models? If you want to stay in the rpicam-apps environment, Raspberry Pi provides a very handy IMX500PostProcessingStage base class which you can derive custom post-processing stages from where you get very granular control over what happens to your output tensors once they make it over to your Raspberry Pi.

If you’re looking to develop a completely custom app you should look into the Picamera2 library. The integration works in much the same way it does with rpicam-apps. There’s an IMX500 helper class which provides all the utilities required for making calls to the sensor from a Python script. There’s a whole lot you can do with it, and Raspberry Pi’s excellent documentation covers it in detail – and there’s even a little demo repository with three Python examples (object classification, detection and segmentation) and a Model Zoo with a whole bunch of ready-made models to be used with these.

But we haven’t yet answered the big question we posed a second ago: what about custom models? In order to bring your own AI model, it’s necessary to pack it into a firmware file. Sony has a set of free tools meant to allow for streamlined model quantization, compression and packaging, allowing you to convert most any PyTorch or TensorFlow model into a compatible format (as long as it can fit the limited memory available on the IMX500). Once uploaded to the Raspberry Pi AI Camera, your custom model is ready to use!

Verdict: AI Camera or AI Kit?

Raspberry Pi currently offers two very different AI solutions. Sure, the software stack used by both is now mostly unified, and the capabilities of the two systems seem broadly similar. With both boasting the same price, how does one choose?

Well, let’s start with the most obvious difference. The AI Camera is a lot less powerful than the AI Kit. With its 13 TOPS of AI compute and PCIe access to gigabytes of system memory, the Hailo-8L is a beefy chip. Come to think of it, it’s probably not too much of a surprise to anyone that a dedicated NPU outperforms one embedded into a sensor – but that’s beside the point.

Quantifying how much faster it is, however, is somewhat problematic. Furthermore, the IMX500’s true Achilles heel is its memory. With just 8 MB at its disposal for pretty much everything AI-related, it’s a real limiting factor. And while the Hailo-8L won’t be running any LLMs either, it certainly takes a lot more to bog it down compared to the IMX500. For crying out loud, some of the heftier models from the Model Zoo run at ~20 FPS at rather low resolutions (256 x 256 and lower).

The AI Kit also offers an (unofficial, for now) upgrade path which we’ve explored a little in our review of it: it’s possible to swap the Hailo-8L module with the Hailo-8, doubling the inferencing performance to 26 TOPS.

This isn’t to say that the IMX500 isn’t a capable little AI accelerator in its own right, as it’s proved its worth in the rpicam-apps demos we’ve ran. For most projects, it’ll be more than enough and it’s a marked improvement compared to running AI models on the Raspberry Pi’s CPU and actually makes real-time inferencing more than possible in a lot of projects.

The only cable you’ll need. | photo: magazin Mehatronika

The AI Camera works on pretty much every Raspberry Pi board you might have, while the Raspberry Pi AI Kit requires a Raspberry Pi 5. And the AI Kit simply packs a lot more bulk, takes up the PCIe connector, requires the use of an adapter HAT+ and a separate camera module on top of that. Over on the AI Camera side, it’s perfectly possible to pair it up with a Raspberry Pi Zero 2 W and end up with a capable setup that’s absolutely minuscule.

It might just be us, but we found the AI Camera a bit easier to use than the AI Kit. Take this with a grain of salt, as both of these have excellent software support and docs, but the former seemed just a tad better integrated with the software, and taking further steps after being done with the demos was just a little simpler.

And finally – price. While both of these systems have the same upfront cost – $70 for both the AI Kit and the AI Camera – unless you’ve got one already, the AI Kit does require you to get a separate camera module. You also have to budget for a Raspberry Pi 5 if you’re still using an older board. This can add up to over $150 if you’re buying all three together. Conversely, even if you’re still using something like a Raspberry Pi 3B, the AI Camera will always set you back just $70.

You can’t really go wrong with either option, but we suspect that most tinkerers and casual users will be more drawn towards the latter. It’s certainly what we’d recommend. Simply grab whatever Raspberry Pi board you’ve got lying around, slap the Raspberry Pi AI Camera on and you’re ready to go. It’s the most sensible way to dip your toes into the world of AI.

In a new video caught by TechCrunch, Boston Dynamics’ humanoid robot Atlas can be seen working autonomously in a demo space, sorting engine parts between numbered bins. The company claims that Atlas doesn’t need to be controlled by humans to do work.

According to the video description, Atlas uses machine learning to detect environmental changes and work around them. It also has a “specialized grasping policy” to help it maintain a firm hold on objects, continuously estimating the state of what it’s holding. After receiving some bin locations to move parts between, Atlas will get to work without prescribed movements, opting to perform tasks independently.

In contrast, Tesla’s Optimus robots were said to receive human remote assistance despite autonomy claims. The Optimus robots were at a live event and, when asked, answered that they were being assisted.

The video shows Atlas sorting and moving the engine parts to designated locations. It does well, transporting them without much awkwardness. After placing one part into a bin, the robot will repeat the process for other parts.

Atlas has undergone plenty of changes since its 2013 reveal, including swapping from hydraulics to electric after almost 11 years of testing. The older Atlas and the current one are markedly different from each other. Take a look at the video below to see for yourself.

Introduction

In recent years, the field of robotics has seen remarkable advancements, with humanoids emerging as one of the most intriguing and promising developments. These robots, designed to mimic human appearance and behavior, are not just a feat of engineering but a reflection of our quest to create machines that can seamlessly integrate into human environments. This article explores the rise of humanoids, their current applications, and the potential they hold for the future.

The Rise of Humanoids: Shaping the Future of Robotics

What Are Humanoids?

Humanoids are robots engineered to resemble the human body, often equipped with a head, torso, arms, and legs. This design enables them to perform tasks in environments designed for humans, making them uniquely suited for roles that require interaction with people. Advanced humanoids are equipped with sophisticated sensors and AI systems that allow them to perceive their surroundings, make decisions, and communicate effectively.

Current Applications

- Healthcare: Humanoids are revolutionizing healthcare by providing assistance to medical professionals and patients. They can perform tasks such as monitoring vital signs, delivering medication, and even assisting in surgeries with precision and reliability.

- Education: In classrooms, humanoids serve as educational tools, helping students learn new concepts through interactive lessons. They can also provide personalized tutoring, adapting their teaching methods to suit individual learning styles.

- Customer Service: From hotels to airports, humanoids are being deployed to enhance customer experiences. They can greet guests, answer queries, and provide information, making interactions more efficient and engaging.

- Elderly Care: As the global population ages, humanoids offer a solution to the growing demand for elderly care. They can assist with daily activities, provide companionship, and monitor health conditions, allowing seniors to maintain independence.

Technological Advancements

The development of humanoids has been driven by breakthroughs in AI, machine learning, and robotics. Advanced algorithms enable these robots to process vast amounts of data, recognize speech, and learn from their experiences. Furthermore, improvements in materials science have led to the creation of more agile and durable humanoid structures.

Challenges and Ethical Considerations

Despite their potential, humanoids face several challenges. Developing robots that can navigate complex human environments safely and effectively remains a significant hurdle. Additionally, ethical considerations such as privacy, security, and the implications of robots replacing human jobs need to be addressed.

The Future of Humanoids

The future of humanoids is filled with possibilities. As technology continues to evolve, these robots will become more capable and accessible, opening up new opportunities across various sectors. Collaboration between researchers, industry leaders, and policymakers will be crucial in ensuring that humanoids are developed and deployed responsibly.

Conclusion

Humanoids represent a fascinating intersection of technology and humanity, offering solutions to some of the world’s most pressing challenges. As we continue to explore their potential, it is essential to balance innovation with ethical considerations, ensuring that these robots enhance our lives while respecting human values. The rise of humanoids marks a new chapter in the story of robotics, one that promises to transform the way we live, work, and interact with the world around us.

China, India, and Mexico: Import-Export Business Overview

China

- Key Exports: Electronics, machinery, textiles, clothing, and medical equipment.

- Key Imports: Integrated circuits, crude petroleum, iron ore, automobiles, and soybeans.

- Trade Agreements: Member of the World Trade Organization (WTO), Regional Comprehensive Economic Partnership (RCEP).

- Opportunities: Growing demand for high-tech products, green technologies, and consumer goods.

- Challenges: Regulatory complexities, stringent quality standards, and intellectual property concerns.

India

- Key Exports: Petroleum products, jewelry, pharmaceuticals, textiles, and information technology services.

- Key Imports: Crude oil, gold, electronics, machinery, and chemicals.

- Trade Agreements: South Asian Free Trade Area (SAFTA), Comprehensive Economic Partnership Agreement (CEPA) with various countries.

- Opportunities: Expanding middle class, demand for infrastructure, and digital services.

- Challenges: Bureaucratic hurdles, infrastructure bottlenecks, and fluctuating currency rates.

Mexico

- Key Exports: Vehicles, machinery, electronics, oil, and agricultural products.

- Key Imports: Electronics, machinery, chemicals, plastics, and steel.

- Trade Agreements: United States-Mexico-Canada Agreement (USMCA), Pacific Alliance.

- Opportunities: Strategic location for North American markets, automotive and manufacturing sectors.

- Challenges: Security concerns, dependence on the U.S. market, and regulatory changes.

Conclusion

The import-export business involving China, India, and Mexico presents significant opportunities due to their large markets and diverse economies. However, businesses must navigate challenges such as regulatory issues, market dynamics, and geopolitical factors. Understanding each country’s trade policies and consumer trends is crucial for successful international trade operations.

Importing and exporting goods around the world involves a complex process that facilitates international trade and stimulates economic growth. This process requires understanding various regulations, tariffs, and trade agreements that govern how goods move between countries. By engaging in global trade, businesses can access larger markets, diversify their product offerings, and reduce costs through economies of scale. Additionally, importing and exporting goods contribute to the global supply chain, fostering innovation and collaboration across different regions. It also allows consumers to enjoy a wider range of products and services, often at more competitive prices. However, successful import and export operations depend on efficient logistics, clear communication, and compliance with international standards and practices.

PCB Board Manufacturing and Applications

Introduction to PCB Boards

Printed Circuit Boards (PCBs) are a crucial component in modern electronic devices, providing the foundation for mounting and interconnecting various electronic components. They are used in a wide range of applications, from consumer electronics to industrial machinery.

Manufacturing Process

- Design and Layout: The process begins with designing the circuit using specialized software, creating a layout that meets the requirements of the electronic device.

- Material Selection: PCBs are typically made from fiberglass, epoxy, or other composite materials. The choice of material depends on the application and required durability.

- Printing the Circuit Pattern: The design is printed onto the board using photolithography, where a photoresist layer is applied and exposed to UV light through a mask, creating the circuit pattern.

- Etching: Unwanted copper is removed from the board using a chemical etching process, leaving only the desired circuit pathways.

- Drilling and Plating: Holes are drilled into the board for component leads, which are then plated with conductive materials to ensure reliable connections.

- Solder Mask and Silkscreen: A solder mask is applied to insulate the board and prevent solder bridges. A silkscreen layer is added for labeling components and guiding assembly.

- Assembly and Testing: Components are mounted onto the board and soldered in place. The assembled PCBs undergo rigorous testing to ensure functionality and reliability.

Applications of PCBs

- Consumer Electronics: PCBs are found in smartphones, computers, televisions, and other household appliances, providing compact and efficient connectivity for complex circuits.

- Automotive Industry: Used in various automotive systems like GPS, engine management, and infotainment systems, offering durability and reliability in harsh environments.

- Healthcare Devices: PCBs are essential in medical equipment such as MRI machines, heart monitors, and other diagnostic tools, ensuring precision and safety.

- Industrial Equipment: They are used in manufacturing machinery, robotics, and control systems, providing robust solutions for high-performance needs.

- Aerospace and Defense: In these sectors, PCBs must withstand extreme conditions, making them integral in navigation, communication, and control systems.

Conclusion

PCBs are a fundamental element in the electronics industry, enabling the development of advanced technologies across various sectors. Their versatility and reliability make them indispensable in the modern world. Whether in everyday gadgets or sophisticated industrial systems, PCBs continue to drive innovation and progress.

The Robotic sector

The robotics sector is poised for significant growth and transformation over the next five years, driven by advances in artificial intelligence, machine learning, and sensor technologies. Here’s what is expected to happen:

- Increased Automation: Industries such as manufacturing, logistics, and agriculture are expected to adopt robots at an accelerated pace to enhance efficiency and reduce labor costs. This will lead to more autonomous systems handling complex tasks.

- AI and Machine Learning Integration: Robots will become smarter as AI and machine learning algorithms improve. These technologies will enable robots to learn from their environments and make decisions in real-time, enhancing their utility in dynamic and unstructured settings.

- Collaborative Robots (Cobots): There will be a rise in the use of collaborative robots that work alongside humans in various settings, from factories to retail. These cobots are designed to be safe, flexible, and easy to program, making them ideal for businesses of all sizes.

- Healthcare Innovations: Robotics in healthcare will expand, with robots assisting in surgeries, rehabilitation, and patient care. This will improve precision in medical procedures and compensate for staff shortages in healthcare facilities.

- Service Sector Expansion: Robots will become more common in the service sector, performing tasks such as cleaning, delivery, and customer service. This will enhance customer experiences and operational efficiency in businesses like hotels and restaurants.

- Personal Robotics: The consumer market will see an increase in personal robots designed for home assistance, security, and companionship. Advances in AI and user interfaces will make these robots more user-friendly and accessible.

- Advanced Robotics in Exploration: Robotics will play a crucial role in space and underwater exploration. Enhanced durability and autonomy will allow robots to explore extreme environments, collecting data and performing tasks that are too dangerous or impossible for humans.

- Ethical and Regulatory Developments: As robotics technology advances, there will be a growing focus on ethical considerations and the development of regulations to manage the impact of robots on society and employment.

- Sustainability and Robotics: Robotics will contribute to sustainable practices by improving energy efficiency, reducing waste, and supporting renewable energy projects.

- Education and Skill Development: With the growing presence of robotics, there will be an increased emphasis on education and training programs to equip the workforce with the necessary skills to work alongside and with robots.

Overall, the robotics sector is expected to revolutionize multiple industries, improve productivity, and create new opportunities, while also posing challenges that will need to be addressed through thoughtful innovation and policy-making.

Semiconductor manufacturing is a complex process that involves the creation of integrated circuits (ICs) used in electronic devices. This process requires precision engineering to produce chips with features measured in nanometers (nm), which is a billionth of a meter. The smaller the nanometer size, the more advanced the technology, allowing for faster and more efficient chips.

Examples of Nanometer Sizes:

- 7nm and 5nm Technology: These sizes are currently in mass production, with companies like TSMC (Taiwan Semiconductor Manufacturing Company) and Samsung leading the charge. They are used in high-performance applications such as smartphones and data centers.

- 3nm Technology: TSMC and Samsung are working towards mass production of 3nm chips, which promise even greater performance and power efficiency. These are expected to be a key technology for future electronics.

- 2nm Technology and Beyond: IBM has announced a breakthrough in 2nm chip technology, although it is not yet in mass production. This advancement represents the cutting-edge of semiconductor research and development.

Global Leaders in Semiconductor Manufacturing:

- TSMC (Taiwan Semiconductor Manufacturing Company): As the largest independent semiconductor foundry, TSMC is a leader in advanced semiconductor manufacturing processes. It has consistently been at the forefront of new nanometer technology, with significant investments in research and development.

- Samsung Electronics: As a major player in both memory and logic chips, Samsung has made significant strides in semiconductor technology. It competes closely with TSMC in the race to develop smaller and more efficient chips.

- Intel Corporation: Although traditionally a leader in semiconductor manufacturing, Intel has faced challenges in recent years with delays in advancing to smaller nanometer processes. However, the company is investing heavily to regain its competitive edge.

- GlobalFoundries: This company focuses on specialized semiconductor manufacturing and has a strong presence in the market, although it does not compete directly in the leading-edge nanometer race.

The race in semiconductor manufacturing is highly competitive, with TSMC and Samsung currently leading in terms of advanced technology node production. The continuous push towards smaller nanometer sizes is driven by the demand for faster, smaller, and more efficient electronic devices, making this an ever-evolving and crucial industry for global technology advancement.

Solar Power Panel Manufacturers and Technologies

- Leading Manufacturers:

- First Solar: Specializes in thin-film solar panels, known for their durability and cost-effectiveness.

- SunPower: Offers high-efficiency solar panels with innovative cell technology, recognized for their durability and performance.

- Canadian Solar: Known for producing high-quality solar modules and providing comprehensive energy solutions.

- JinkoSolar: One of the largest solar module manufacturers, offering a wide range of products with competitive pricing.

- Trina Solar: Provides advanced solar panel solutions and is a leader in technological innovations.

- Emerging Manufacturers:

- LONGi Solar: Focuses on monocrystalline silicon solar modules, known for high conversion efficiency.

- JA Solar: Produces high-performance PV products and has a strong global presence.

- Risen Energy: Offers innovative, sustainable solar solutions and high-efficiency panels.

- Advanced Technologies:

- Monocrystalline Silicon Panels: Known for higher efficiency and sleeker aesthetics, these panels are made from a single crystal structure.

- Polycrystalline Silicon Panels: Generally more affordable, made from silicon crystals that are melted and reformed.

- Thin-Film Solar Panels: Lightweight and flexible, ideal for unconventional installations, although usually less efficient.

- Bifacial Panels: Capture sunlight from both sides, increasing energy yield and efficiency.

- PERC Technology (Passivated Emitter and Rear Cell): Enhances cell efficiency by reflecting unabsorbed light back into the cell for better energy conversion.

- Innovative Approaches:

- Perovskite Solar Cells: Emerging as a promising technology due to their potential for high efficiency and low production costs.

- Floating Solar Panels: Installed on bodies of water, they help conserve land space and reduce evaporation.

- Building-Integrated Photovoltaics (BIPV): Integrates solar panels into building materials, such as roofs and facades, for seamless energy generation.

- Sustainability and Future Trends:

- Focus on reducing carbon footprints and enhancing the recyclability of solar panels.

- Development of smart solar panels that integrate with energy management systems for optimized performance.

- Continued research into hybrid solar systems combining photovoltaic and thermal energy capture.